About Energy

About Marine

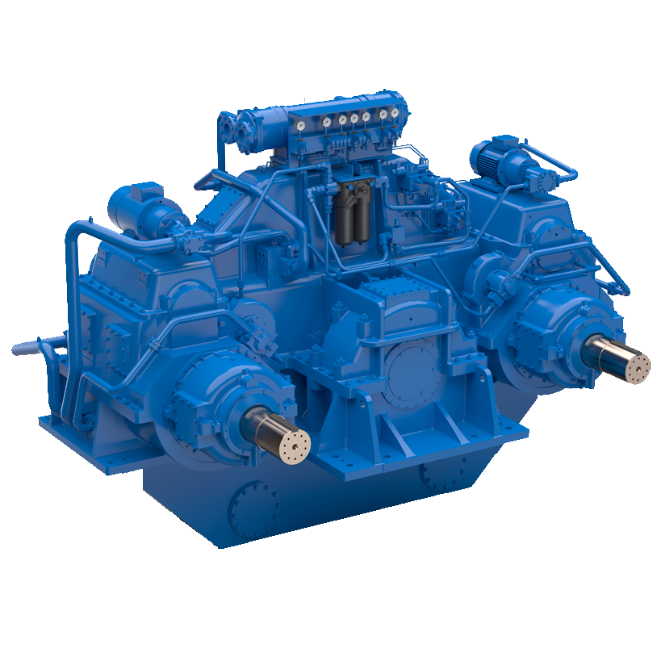

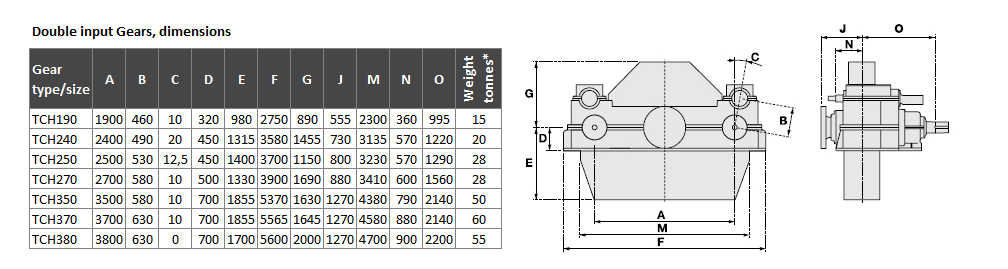

Wärtsilä double input, single stage reduction gears connect two engines to a single propeller shaft and cover a power range from 2,000 to 25,000 kW. The gears are available with a horizontal offset between the input shafts and output shaft to allow two (diesel) engines to be connected.

Options:

Application

Double input gears are applied to combine the output power of 2 medium speed diesel engines on a single propeller shaft. Typical applications include:

A key dimension of a double input gear is the horizontal offset, which is determined by the required service space between the two propulsion engines. Wärtsilä double input gears can be combined with Wärtsilä engines, as indicated in the table below, as well as with other engine brands.

Technical Info

Download drawings

All Wärtsilä gears can be supplied with one or more PTOs for driving the shaft alternator, compressor or pump. For single vertical and horizontal gears, the standard PTO is primary driven. For double gears, the PTO is optionally primary or secondary driven.

A primary driven PTO rotates whenever the engine is rotating.

A secondary driven PTO rotates whenever the propeller shaft is rotating.

Most Wärtsilä gears can be supplied with a combined PTO/PTI. In PTI mode the shaft alternator can also be used as an electric motor. PTI is normally used for the following operational modes:

PTI “Booster” mode is used when the main power of the engine is insufficient in order to increase the total propulsion power. For this mode, no clutches are required on the gear.

PTI “Take me home” mode is used in case of emergency should the prime mover be inoperable. For this mode a minimum of 2 clutches are required on the gear.

Most Wärtsilä gears are purpose-designed with an integrated hydraulic system for both the gear and the CP propeller. As a separate hydraulic power unit for the CP propeller is superfluous, both installation costs for the yard and operational costs for the owner are reduced. For safety reasons the gear mechanically drives the main pump for the propeller. All gears can also be interfaced with a separate hydraulic power unit.

Based on the standard Wärtsilä gear types, customized solutions can be delivered upon request.

Examples:

Expand all

Collapse all