About Energy

About Marine

If you are considering a switch to low-carbon fuel, methanol is an attractive option. Green methanol has the potential to be carbon free, and it meets current and future emissions targets in terms of NOx, SOx and particulates. This makes methanol as marine fuel an attractive choice for any type of vessel and can help owners and operators on their path to a greener future.

Want to know more about the pros and cons of methanol as a marine fuel? Quickly discover the key facts on this handy one-page cheat sheet.

If you’re currently using diesel, switching to a methanol engine will reduce your emissions. This can significantly improve your EEXI (Energy Efficiency Existing Ship Index) and CII (Carbon Intensity Indicator) ratings.

While the energy transition is in process, vessels are unlikely to be operated on the same fuel for their entire lifecycle. In addition to methanol, there are many other sustainable marine fuels. This page summarises the latest in future fuels development.

If you’re currently using diesel, switching to methanol will reduce CO2 (tank-to-wake) emissions by up to 7%, SOx emissions by up to 99% and NOx emissions by up to 60% compared to heavy fuel oil (HFO) operation. Green methanol, produced using renewable energy, has the potential to be a carbon-free fuel.

Learn more about green methanol and the other methanol “colours”: “Methanol as marine fuel – is it the solution you are looking for?”

Choosing between methanol and other decarbonisation solutions depends on both fuel availability in your operating area and which solutions make the most technical and economic sense for your vessel.

The technology for using methanol is already available and proven in the field, with 22 vessels currently operating on methanol according to DNV. Two of these – a RoPax vessel and a pilot boat – are conversions with 4-stroke engines; the rest are tankers fitted with 2-stroke engines that were designed in the newbuild stage to enable methanol operation.

Discover four real-life examples – one each from the cruise, ferry, merchant and offshore sectors. Learn how operators are already using methanol to solve their challenges, and how you can start using it to reduce emissions immediately.

When building a vessel to run on methanol, the vessel design must allow room for fuel storage, equipment, pipes and trunks.

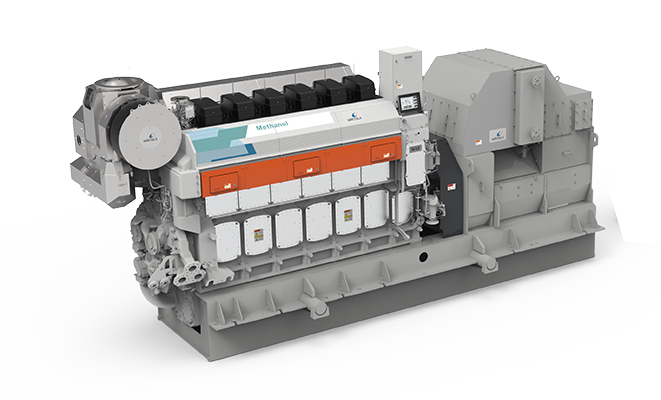

Wärtsilä is developing a broad portfolio of methanol engines and the fuel supply systems to help ship owners reduce their greenhouse gas emissions. Wärtsilä is one of the few marine engine builders to have experience with methanol engines and dual-fuel methanol-diesel engines. For example, Wärtsilä was the first to introduce a fuel-flexible large-bore medium-speed 4-stroke engine, which the Stena Germanica ferry has been operating on methanol since the year 2015. The Wärtsilä 32 Methanol engine is currently available for delivery from the factory.

If you’d like to discuss whether a methanol engine might be the right choice for your newbuild project, get in touch for a no-obligation discussion including the facts and figures you need to make your decision.

If you’re considering converting an existing vessel to run on methanol, there are many factors to consider. You would either need a methanol engine conversion or replace existing engines with methanol-capable engines such as the Wärtsilä 32 Methanol. In addition, certain auxiliary, safety, and control systems would need to be fitted onboard and methanol tanks would need to be added.

Wärtsilä can assist in initial decision-making by providing:

We can also supply the key equipment for methanol operation, convert your existing engines to run on methanol or provide new methanol engines.

Want to know more? Simply contact Wärtsilä to discuss your options, or for a full and no-obligation feasibility study.

Read more about your options for methanol-fuelled vessels.

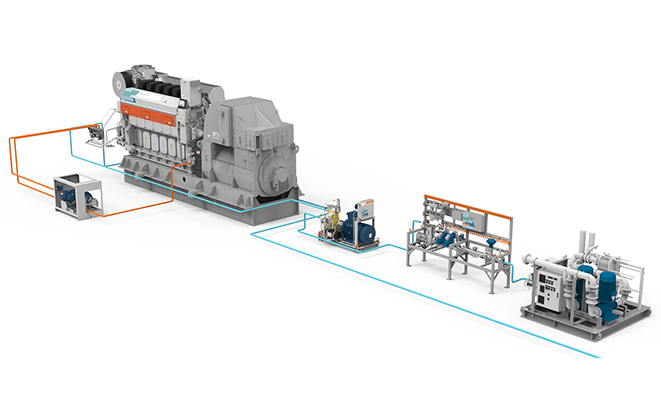

Discover a future-proof methanol-powered system capable of reducing emissions and contributing to maritime decarbonisation. From the engine, through storage and fuel handling to emissions reduction, you can benefit from receiving the whole, fully integrated solution from one supplier.

Before the methanol gets to the engine, Wärtsilä MethanolPac provides a complete fuel supply system including the bunkering station, tank-related equipment, and methanol process equipment as well as the control and monitoring system.

The Wärtsilä 32 engine has been the preferred choice of yards, operators and owners since the 1980s, with more than 5,300 engines delivered to the marine market. The Wärtsilä 32 Methanol builds on this history and pioneers a new era of lower-carbon operations.

When burned as a fuel in a methanol engine, methanol produces 50% less NOx than fuel oil, making the Wärtsilä 32 Methanol engine compliant with IMO Tier II limits. But when combined with selective catalytic reduction such as Wärtsilä’s NOx Reducer (NOR), the engine meets IMO Tier III limits.

The Wärtsilä 32 Methanol engine can run on methanol and/or fuel oils. Because methanol combustion produces 50% less NOx than fuel oil, the Wärtsilä 32 methanol engine is compliant with IMO Tier II limits.

A complete fuel supply system for methanol-fuelled ships. It ensures the safe handling of methanol.

An emission after-treatment system based on selective catalytic reduction (SCR) technology for nitrogen oxide (NOx) reduction. Add the NOR to your Wärtsilä engine and the combination will meet both IMO Tier III and EPA Tier III regulations.

Converting your existing vessel to run on methanol is one way to decarbonise your fleet and improve a vessel’s EEXI and CII ratings. Wärtsilä has been investing in engine conversion technology for over a decade, with engine conversions that have already successfully run on methanol for many years. Each conversion is a complete project starting from initial feasibility studies, design and engineering to engine conversion and installation of related equipment such as tanks, piping and safety systems. Every vessel requires a tailored approach, and Wärtsilä guides you throughout the whole process.

Engine conversion technology is currently available for ZA40S engines and will also soon be available for Wärtsilä 32 and 46F engines.

The 4-stroke methanol conversion is a complete solution to retrofit existing vessels to use methanol as fuel. The scope includes engine conversion, fuel handling systems and automation and control systems, and Wärtsilä guides you throughout the process from engineering to implementation.

The 2-stroke future fuels conversion deploys innovative fuel injection technology to significantly reduce integration complexity, capital cost and onboard footprint – bringing the environmental advantages of LNG and future fuels within reach of an even wider range of vessels.

Take your easiest next step! Get in touch and let’s discuss your options, or for a full and no-obligation feasibility study.