About Energy

About Marine

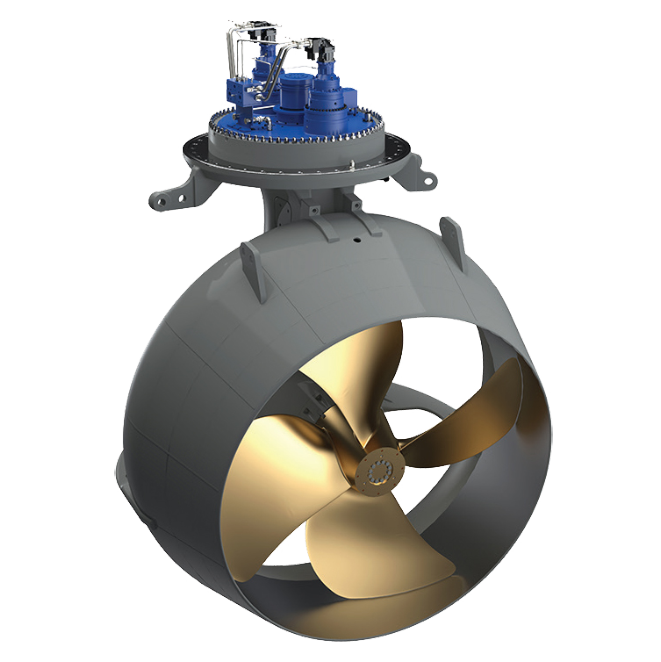

The Wärtsilä underwater mountable thruster are designed for safe and reliable operation under demanding conditions. The proven underwater mounting method enable maintenance to the thrusters with the vessel afloat, taking out the need for dry-docking of the vessel.

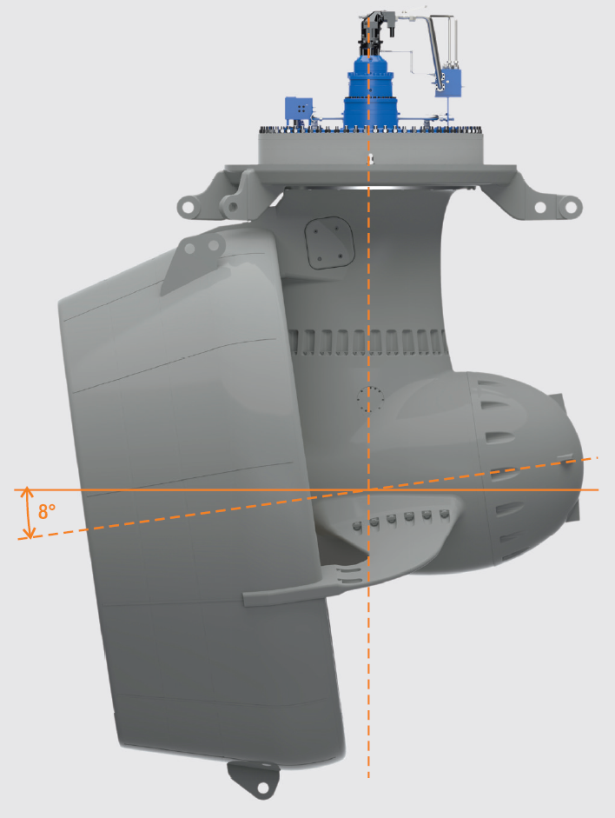

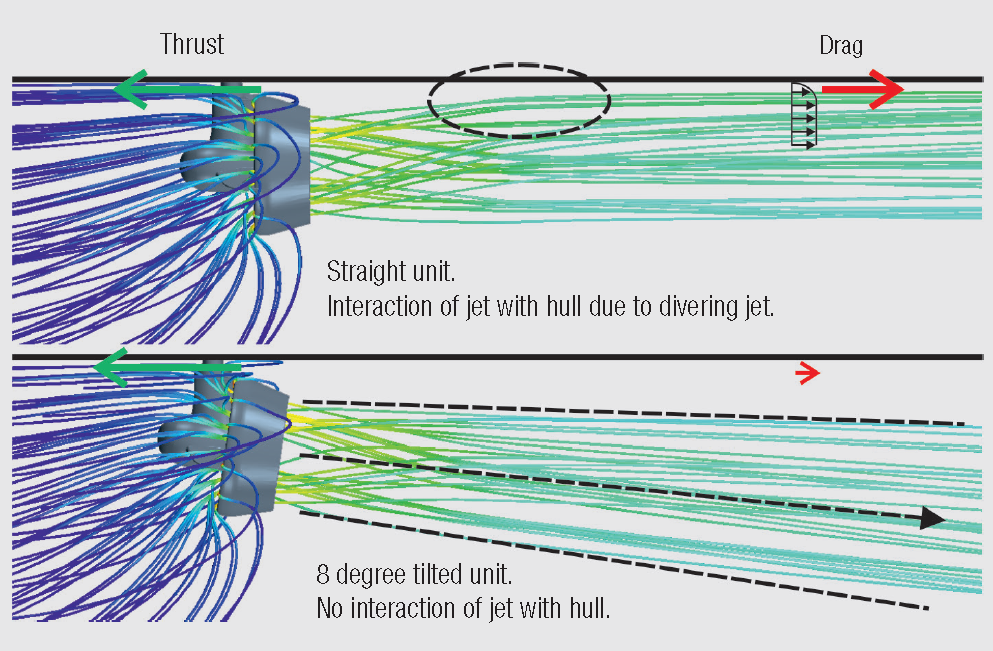

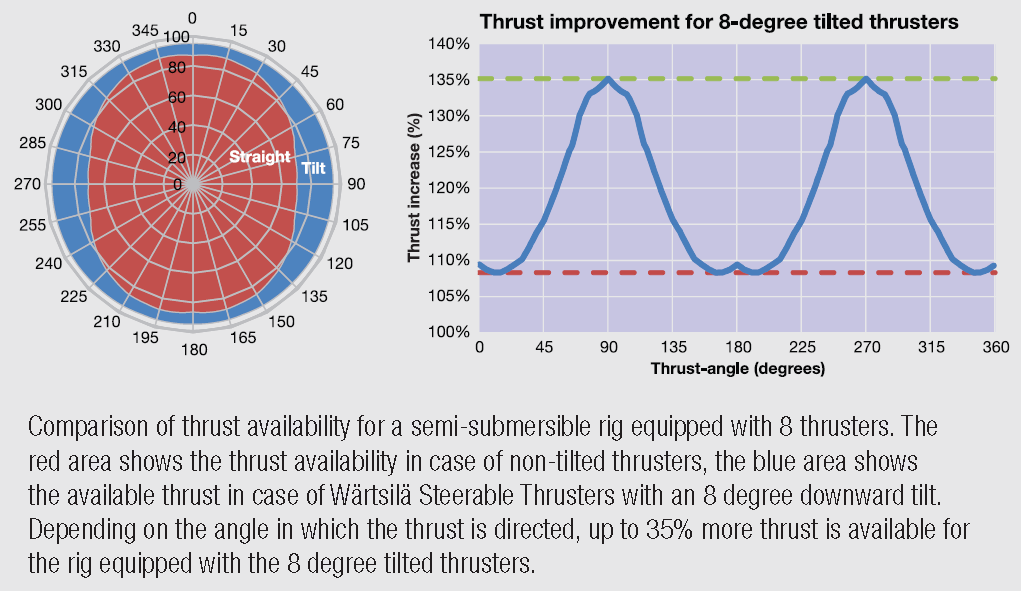

The underwater mountable thruster features an optimised design and the Wärtsilä Thruster Nozzle to provide excellent bollard pull performance. By the 8° tilted propeller gearbox the thruster-hull interaction losses are significantly reduced. The benefits of the underwater mountable thrusters enable superior and reliable DP performance.

Application

Technical Info

Main technical data

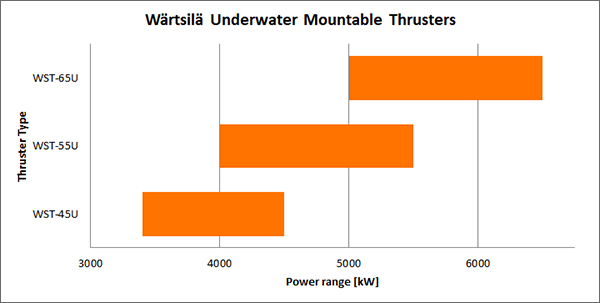

| Thruster type | Power (1) [kW] |

Input speed [rpm] |

Propeller diameter (A) [mm] |

Tilt | |

|---|---|---|---|---|---|

| WST-45U | 4000 4500 |

720 600 |

3600 | 8° | |

| WST-55U | 4500 5500 |

720 600 |

3900 | 8° | |

| WST-65U | 5500 6500 |

720 600 |

4200 | 8° | |

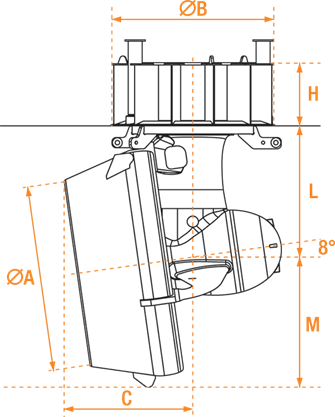

Weights and Dimensions

| Thruster type | A | B | C | M | L | H | Outboard part1 |

Well2 | ||

|---|---|---|---|---|---|---|---|---|---|---|

| dry | in water | |||||||||

| WST-45U | 3600 | 3300 | 2518 | 2324 | 2570 | 1241 | 51000 | 34500 | 9500 | |

| WST-55U | 3900 | 3625 | 2648 | 2516 | 2763 | 1390 | 63500 | 41800 | 11900 | |

| WST-65U | 4200 | 3820 | 3006 | 2719 | 3025 | 1390 | 77500 | 49500 | 13200 | |

Power ranges

WST-RU

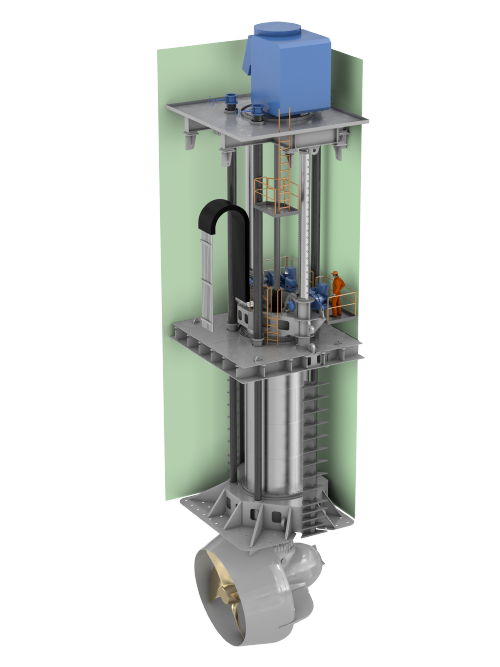

The Wärtsilä Retractable Underwater Mountable Thruster (WST-65RU) has been designed to meet the needs of large offshore vessels (OCVs) as well as semi-submersible rigs and drill ships.

With the power output of 5500kW it is typically designed for vessels that require thrusters that can be retracted during transit or while entering shallow waters. The thrusters can be mounted or de-mounted while the vessel is afloat. Additionally, the ability to retract and deploy the thruster enables an increased level of operational flexibility.

The thrusters feature a unique combination of retractable and underwater mountable functionality.

The WST-65RU is based on the WST-65U underwater mountable thruster which has been designed with performance and reliability as key requirements. The eight degree tilted propeller shaft solution is a feature of the Wärtsilä Underwater Mountable Thruster that reduces the interaction between the thrusters and hull significantly, thereby enhancing the dynamic positioning performance of the vessel. The thrusters are equipped with Wärtsilä Oceanguard anti-pollution face type seals, which have been selected primarily because of the challenging environments in which these thrusters will operate.

In combination with Wärtsilä PCMS (Propulsion Condition Monitoring Service) downtime and maintenance costs can be minimized.

Key benefits:

Each component and aspect of the underwater mountable thruster series has been selected to achieve a high level of reliability. With the Wärtsilä PCMS (Propulsion Condition Monitoring Service), the reliability and availability of the thruster can be improved even further. As this service is recognized by the main marine class societies, the thruster overhaul intervals can be extended according to the condition of the equipment

The Wärtsilä Underwater Mountable Thruster series feature an 8 degree tilted propeller shaft and nozzle, which direct the propeller jet away from the hull and other thrusters. In addition to reducing hull interaction losses, this also greatly reduces interaction between the thrusters, thus making the so-called ‘forbidden zones’ considerably smaller. The unique design means that customers can expect up to 20% more effective thrust than conventional non-tilted thrusters, depending on vessel configuration and application.

The excellent efficiency and performance of Wärtsilä Underwater Mountable Thruster are further enhanced by the capability to design and configure the optimal configuration and power requirements to fit the vessel actual operating profile and needs of the owner. This is achieved through the use of advanced calculations including hydrodynamics and computational fluid dynamics (CFD) and includes the ability to add system failures to ensure safe operation. The result of these calculations and analysis allow for an accurate view of the thruster position, combination of thruster type, and most importantly the power required to deliver the thrust to support vessel operations safely and efficiently – this detailed insight allows the correct total vessel power requirement to be calculated rather than estimated, which can reduce the cost of the total power train configuration.

By bringing together these technologies and expertise in a single configurable solution approach, the optimal solution can be agreed, which when combined with Wartsila’s thruster performance results in reduced overall weight and increased performance. This ensures that owners, operators and yards benefit from significant savings and efficiencies not before possible.

Effective DP operations

The three largest thrusters within the Wärtsilä Underwater Mountable Thruster series feature an 8 degree tilted propeller shaft and nozzle, which direct the propeller jet away from the hull and other thrusters. In addition to reducing hull interaction losses, this also greatly reduces interaction between the thrusters, thus making the so-called ‘forbidden zones’ considerably smaller. The overall gain in effective bollard pull thrust for dynamic positioning operations is about 15% when compared to conventional units.

High efficiency

The Wärtsilä Underwater Mountable Thruster series features the Wärtsilä thruster nozzle to provide excellent bollard pull performance.

First class reliability

Each component and aspect of the underwater mountable thruster series has been selected to achieve a high level of reliability. With the Wärtsilä PCMS (Propulsion Condition Monitoring Service), the reliability and availability of the thruster can be improved even further. As this service is recognized by the main marine class societies, the thruster overhaul intervals can be extended according to the condition of the equipment.

Compact and with less weight

Detailed FEM analyses have been made to optimize the strength of the components so as to keep the overall weight as low as possible. Compact dimensions result in less space requirements in the thruster room and more payload capacity for the vessel.